1.Mining industry filter

Comprehensive, smart and sustainable dewatering solutions for the toughest mining applications in concentrates and tailings coupled with an unmatched global service portfolio and expertise.

Contact our sales experts

Our concentrate filtration solutions are one of the most efficient in the industry, based on energy consumption duties and environmental impact. They are designed for maximum & standard-surpassing operational safety.

2. Mining filter presses

2. Mining filter presses

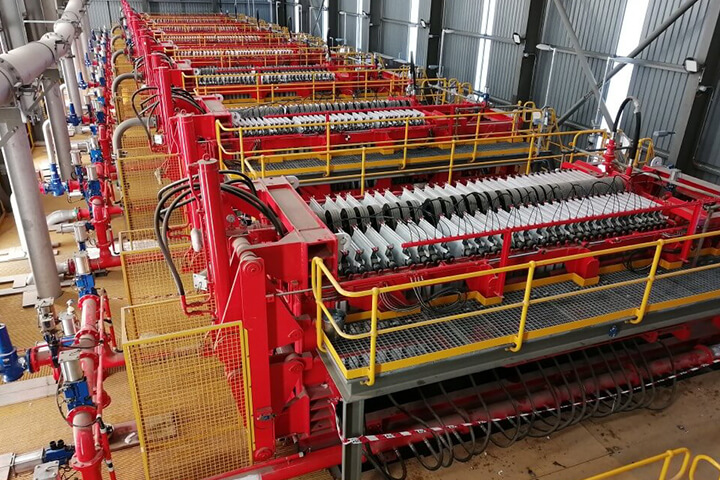

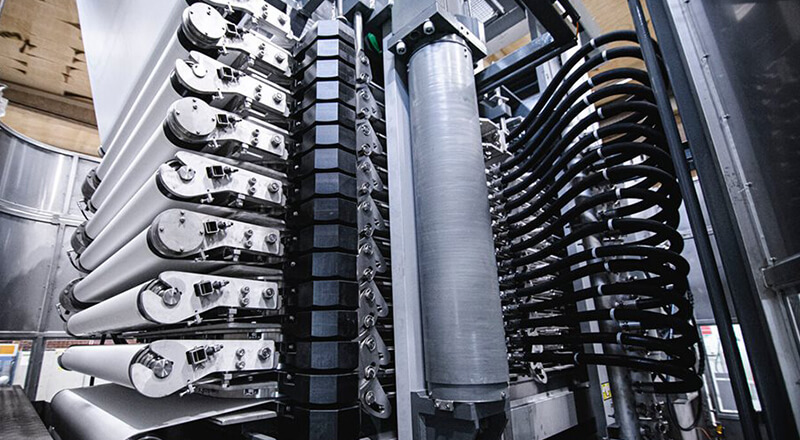

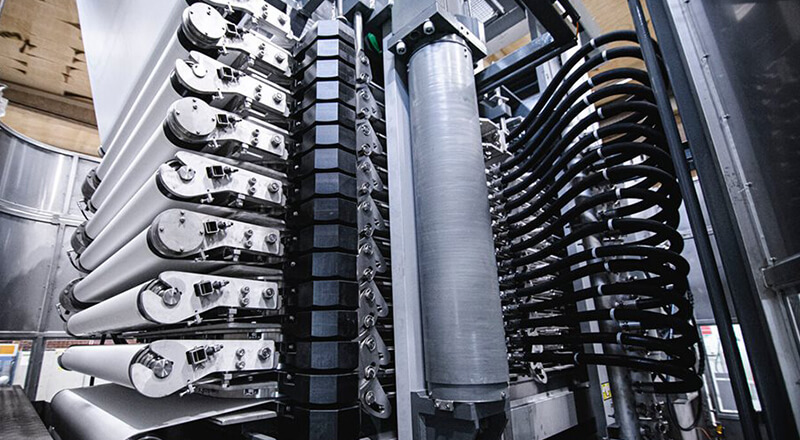

Filter presses are used in processing plants of the mining industry due to the positive aspect of the great process-technical flexibility among other things. The most frequent applications are the dewatering of fine coal and coal tailings (finest fractions) as well as the solid-liquid separation of the ore concentrate suspension concentrated by flotation and subsequently separated from mineral by-products. At this point, metals such as zinc, iron and copper are extracted, but precious metals such as gold, silver and platinum are also extracted in corresponding mines in the form of a puncture-proof filter cake. Membrane filter presses are preferably used here to achieve quantitatively high yields in cake washing and high dry matter contents by means of squeezing processing.

Our filter presses – with their adapted dewatering technology and the associated special design-typical features for this application – enable a fast cycle time, high filtration speeds during filtration and dewatering of the suspensions as well as a low residual water content of the resulting filter cake solids. These properties and an optimised and efficient design of the processes for the application are of great importance with regard to the requirement for high capacities and above all from an economic point of view.

3. Mining Water Filter

3. Mining Water Filter

Regardless of the resource being mined, water is used for a variety of purposes in mining operations. Water in mine processes may be corrosive, and require the use of corrosion resistant mining water filters. Common filtration applications at mining sites include effluent filtration, intake filtration, process water filtration for dust mitigation systems, wash water, process reuse filtration, precious metal extraction solutions (heap leach) etc. HENAN ANJUN self-cleaning filters for mining operations are also available from 304 & 316L stainless, Duplex/Super Duplex Stainless, and more. HENAN ANJUN specializes in custom, highly engineered equipment designed to operate in the most demanding environments with minimal water loss.