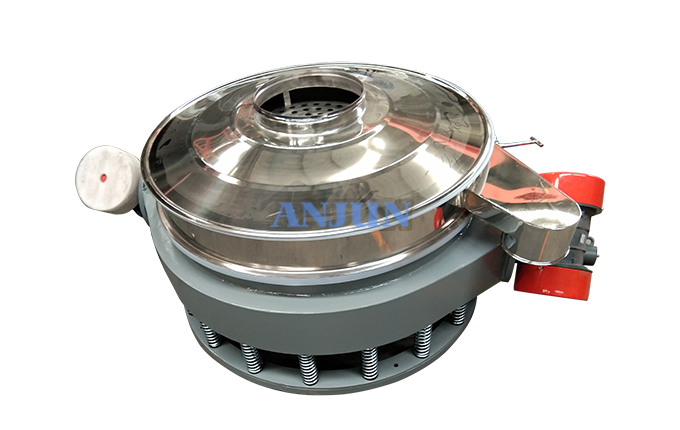

Direct discharge grading screen from China

Straight row vibrating screen, widely known as "safety officer", It is connected to the production system and the automatic sorting speed is much faster than other types of sieving machines. It adopts high frequency vibration motor as excitation source. After the material enters the screen machine, it is subjected to three-dimensional rotary motion on the screen surface by the vibration source force. Powder and agglomeration are fully dispersed and rapidly separated. Qualified materials enter the lower chamber, and foreign bodies and large particles are discharged to the slag discharge port.

It is mainly used for coarse screening and precise screening of granular powder in flour, starch, washing powder, metal powder,additives, chemical industry, non mineral industries, etc., with large processing capacity and easy integration with production lines. It can be selected from 600MM to 1800MM.